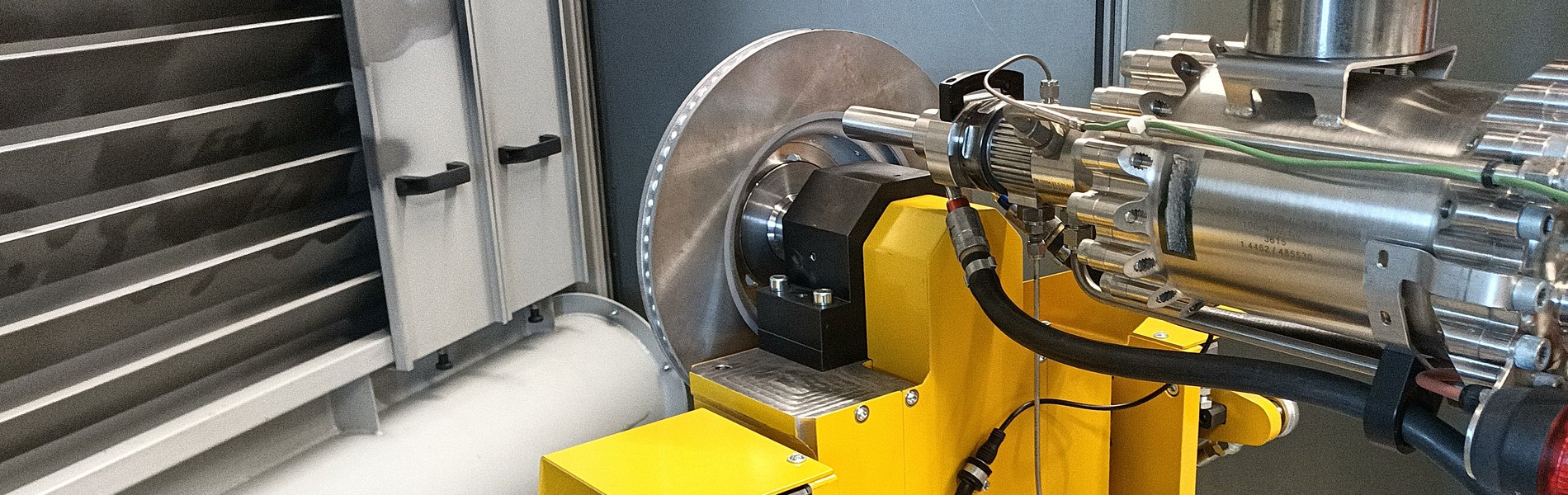

Exemplary solution – Brake disc coating for South German OEM in automobile industry

Lower emissions, less wear and corrosion – by the IMPACT-Hyrid-Brake-Disc-Coatings, these and also further requirements to brake discs can be guaranteed.

INACORE sets the highest quality standards for themselves and the process used.

After pre-treatment of the brake discs, the coating used consists of a base layer applied by high-speed laser metal deposition and a friction layer applied by a cold-gas-spray process. By using both of the processes, the advantages of a strong metallurgical bond through the laser metal deposition and the advantages of a crack-resistant, low-tension and corrosion-resistant cold-gas-spray coating can be combined.

INACORE therefore offers a simple, cost-effective and extremely high-performance solution to the challenges of the automotive industry associated with the EU7 standard.

Advantages of the coating system:

- Selection of different powder systems depending on coating requirements

- Successful regarding durability, braking behavior and particulate emission

- Minimal thermal influence on the brake disc, low distortion leads to lower coating and grinding costs

- Highest bonding strength between brake disc and coating

- Wide selection of different powder combinations with corresponding effects on coating costs